Significant leakages will generally be turbulent, and it is the fluctuating pressure field generated by this turbulence which gives rise to the AE signal. This signal is then transmitted through the fluid and valve wall and so can then be detected on the outside of the valve. The AE signals are generated across a wide range of frequencies, but using very high frequency detectors (60 kHz to 600 kHz) the low frequency, audible background noise is filtered out. Hence, the technique can be used in noisy plant environments, for example adjacent to compressors and pumps. The MIDAS Meter® measures the RMS value in decibels of the AE signal at the point of contact of the sensor with the valve.

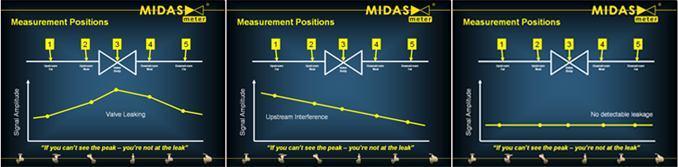

The survey technique requires the test valve to be closed, with a known differential applied across the valve. The pressure difference ideally should be greater than 10 BAR. Leakages can be detected at lower pressures, but with a loss of sensitivity. The sensor is then held in contact with the valve on a flat clean surface using an acoustic couplant such as silicone grease. Several points on the valve body are measured, and the highest stable reading is then recorded. Background readings on the up and downstream pipework are then taken to ensure that it is the valve that is the source of the leakage noise, and not an adjacent valve. As measurements are taken in the high frequency range, the recorded AE signal will attenuate rapidly with distance from its source. This enables the source of the AE signal to be easily located. This becomes highly valuable when dealing with closely spaced valves on manifolds where there are many potential leak paths.