Acoustic Emission (AE) is a term normally associated with high frequency sounds or vibrations that are emitted from materials or structures under load and potentially approaching failure. The high frequency sounds or vibrations are the stress waves produced by the sudden internal redistribution of stress within the materials caused by changes in the internal structure of the material. Crack growth due to fatigue, hydrogen embrittlement, stress corrosion, and creep can be detected and located by the use of AE technology. AE technology is also widely employed in the non-destructive testing for structural integrity of materials and structures made from composite materials. Fiber breakage, matrix cracking, and delamination are three mechanisms that can produce AE signals when stress is applied to the material or structure.

AE techniques have been in use for decades to detect leaks in pressurized piping. If the surface of the pipe is exposed, the location of the leak can sometimes be determined by visual methods. If the pipe is coated or buried or otherwise concealed, one can sometimes estimate the approximate location by measuring the amplitude of the acoustic emission signals produced by the leak. If a leak occurs due to the growth of a fatigue crack at high pressures, it tends to “weep” one drop at a time (for liquids) and does not leave much visual evidence of its presence. In this situation the leak is easily detected by acoustic emission techniques but not so easily located based on the amplitude of the acoustic emission signal or visual methods without sophisticated signal processing techniques.

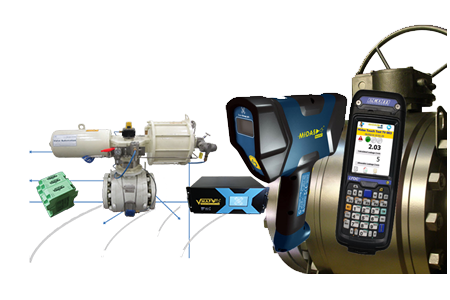

Several different signal processing techniques are routinely employed in order to properly capture, analyse and interpret AE events. Different AE sensor and signal processing techniques are used based on the component and structure under test and the expected signal level of the noise or vibration of interest. AE equipment can be specifically tuned to respond to frequencies normally associated with the leakage of pressurized fluid or gas through a small opening to a lower pressure area inside a pipe or valve and is thus an effective tool for detection of leakage (passing) in valves that are expected to provide tight shutoff. Score has taken this one step further by developing algorithms that can estimate the actual leakage rate in many applications.