Every Valve’s performance deteriorates over its life cycle, so valve management and maintenance is critical if you want to avoid unplanned shutdowns, high potential risks and high costs. Check out our video for more information on how Score Diagnostics can help you reduce costs, minimise risks and maximise efficiency.

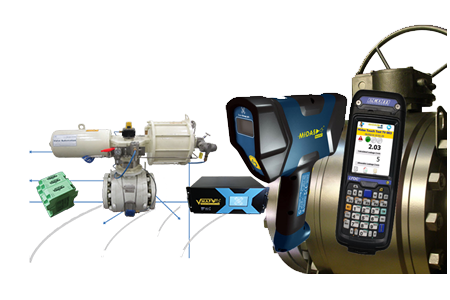

Score Diagnostics Limited is a leader in valve leak detection, quantification and trending and in the design and manufacture of a range of valve condition and performance monitoring equipment and systems. The MIDAS® Valve Diagnostics Range of products is exclusive to Score Group plc, and currently includes the MIDAS Meter®, MIDAS® Sensor and V-MAP® G3.

MIDAS Meter® is designed to support Process Owners and Operators in markets where valves have a critical role to play in isolating process flow. This hand held, easy to use, non-invasive inspection equipment is capable of quickly and easily identifying leaking valves. Once a leaking valve is identified, the equipment can then quantify and trend the valve’s leak rate over time, guiding the maintenance and valve management decision making process, using an evidence-based approach to minimise costs and risks and maximise uptime, efficiency and profitability.

MIDAS Meter® is potentially the most powerful cost-saving tool you could ever have in your toolbox. It has the capability to safely reduce valve maintenance costs and at the same time, maximise efficiency on your process plant. Within minutes of condition monitoring valves with MIDAS Meter®, you can be identifying your problem valves as well as saving costs. Targeting your maintenance spend on only your problem valves will maximise the efficiency and profitability of your production. View our video to hear more.

If you are new to our technology and our MIDAS Meter® product, but are looking for additional information on what it does / how it works and what some of the benefits of using it may be, we highly recommend you view this simple video demonstration now. In this video, you will learn about the three levels of operation and when / how these help you meet your operational needs to manage safety, reliability and optimise production through Intelligent Valve Management™.

We put the non-invasive testing tool, MIDAS Meter®, to the test to see how quickly and easily valve sealing integrity can be checked. Watch the video to find out the result.

MIDAS® Sensor is designed to be permanently installed on medium to high criticality valves which are required to perform isolating functions. The purpose of the MIDAS® Sensor is to continuously monitor the valve’s sealing capability and report on performance over time. Based on the same operating principal as the MIDAS Meter®, the sensor gives maximum visibility and assurance levels of valve performance (or not). MIDAS® Sensor’s output can be integrated into existing plant operating and management systems.

Score’s enhanced V-MAP® G3 system gives process plant owners, integrity and safety assurance engineers, and maintenance personnel enhanced visibility of critical valve condition and performance indicators. This makes developing failure modes in valves and their actuators quickly and easily identifiable. V-MAP® G3 further extends the Score range of diagnostic equipment available for monitoring valves’ in-service performance over time.

Every Valve’s performance deteriorates over its life cycle, so valve management and maintenance is critical if you want to avoid unplanned shutdowns, high potential risks and high costs. Check out our video for more information on how Score Diagnostics can help you reduce costs, minimise risks and maximise efficiency.

Score Diagnostics Limited is a leader in valve leak detection, quantification and trending and in the design and manufacture of a range of valve condition and performance monitoring equipment and systems. The MIDAS® Valve Diagnostics Range of products is exclusive to Score Group plc, and currently includes the MIDAS Meter®, MIDAS® Sensor and V-MAP® G3.

MIDAS Meter® is designed to support Process Owners and Operators in markets where valves have a critical role to play in isolating process flow. This hand held, easy to use, non-invasive inspection equipment is capable of quickly and easily identifying leaking valves. Once a leaking valve is identified, the equipment can then quantify and trend the valve’s leak rate over time, guiding the maintenance and valve management decision making process, using an evidence-based approach to minimise costs and risks and maximise uptime, efficiency and profitability.

MIDAS® Sensor is designed to be permanently installed on medium to high criticality valves which are required to perform isolating functions. The purpose of the MIDAS® Sensor is to continuously monitor the valve’s sealing capability and report on performance over time. Based on the same operating principal as the MIDAS Meter®, the sensor gives maximum visibility and assurance levels of valve performance (or not). MIDAS® Sensor’s output can be integrated into existing plant operating and management systems.

Score’s enhanced V-MAP® G3 system gives process plant owners, integrity and safety assurance engineers, and maintenance personnel enhanced visibility of critical valve condition and performance indicators. This makes developing failure modes in valves and their actuators quickly and easily identifiable. V-MAP® G3 further extends the Score range of diagnostic equipment available for monitoring valves’ in-service performance over time.