Whilst MIDAS Meter® has an extensive field-proven track record of adding value in the in Oil & Gas, Petrochemical, Nuclear and Fossil Fuel Power Generation industries, it had never previously been used on a Biomass Energy Plant.

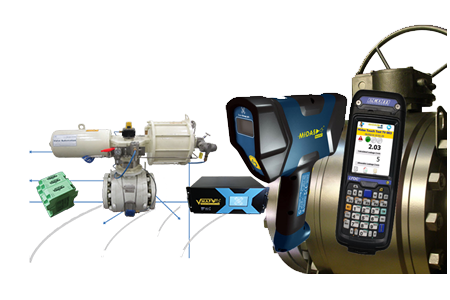

All that changed however, when it made its debut on a plant in Europe this month. Score Diagnostics Limited’s valve leak detection, quantification and trending device was used to verify the sealing capability / performance of critical process valves, as part of a product demonstration.

A number of valve designs and sizes were tested, some of which were operating at high temperatures. Following each individual valve test, the results were immediately passed on to the plant maintenance engineer and a full summary report for all valves, (including performance graphs and deeper analysis data) was produced immediately after the survey, before leaving the facility.

With the customer suitably impressed with the ease of use, performance of MIDAS Meter® and the immediate reporting of results, the discussion quickly turned to how it could support reliability centred maintenance programmes and specifically assist in moving towards a predictive maintenance approach.

We are looking forward to implementation of the technology on a Risk Based Inspection (RBI) strategy and to adding increasing value for our customers as part of an optimised valve management programme.