We are excited to share that we have recently hit the 2k+ follower mark on our LinkedIn showcase page.

A huge thank you goes out to everyone who follows us, likes our posts, and shares our content.

We really appreciate your support and enjoy engaging with you.

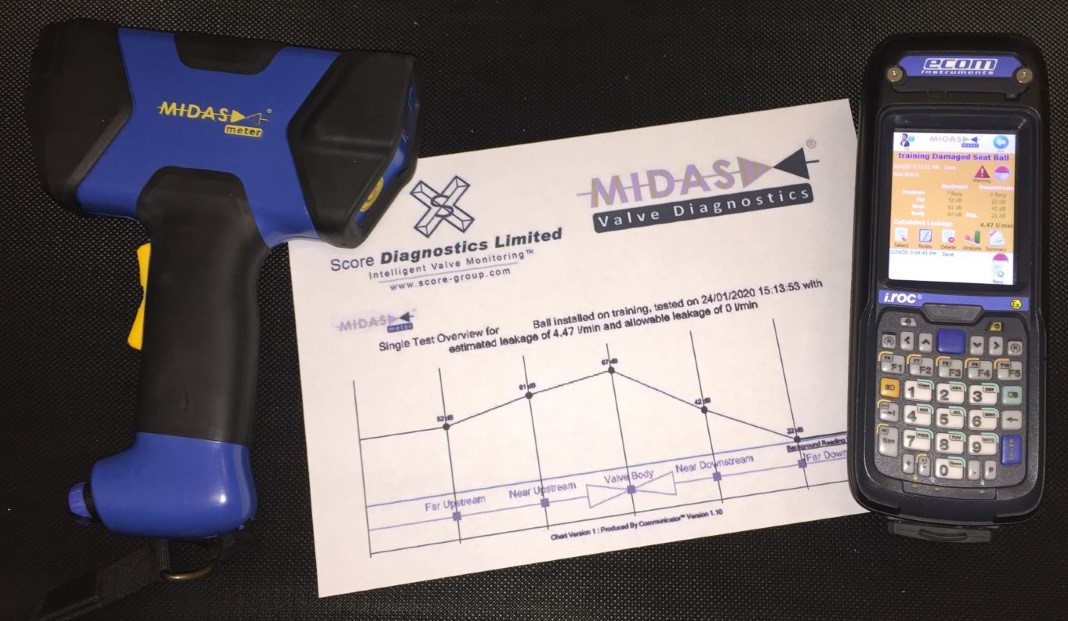

Not a follower yet? We’d love it if you joined our LinkedIn community. Visit our page and then click the blue “+Follow” button to be the first to find out about Score Group Valve Condition & Performance Monitoring Equipment, Systems & Services to help you to keep your processes running safely & efficiently.