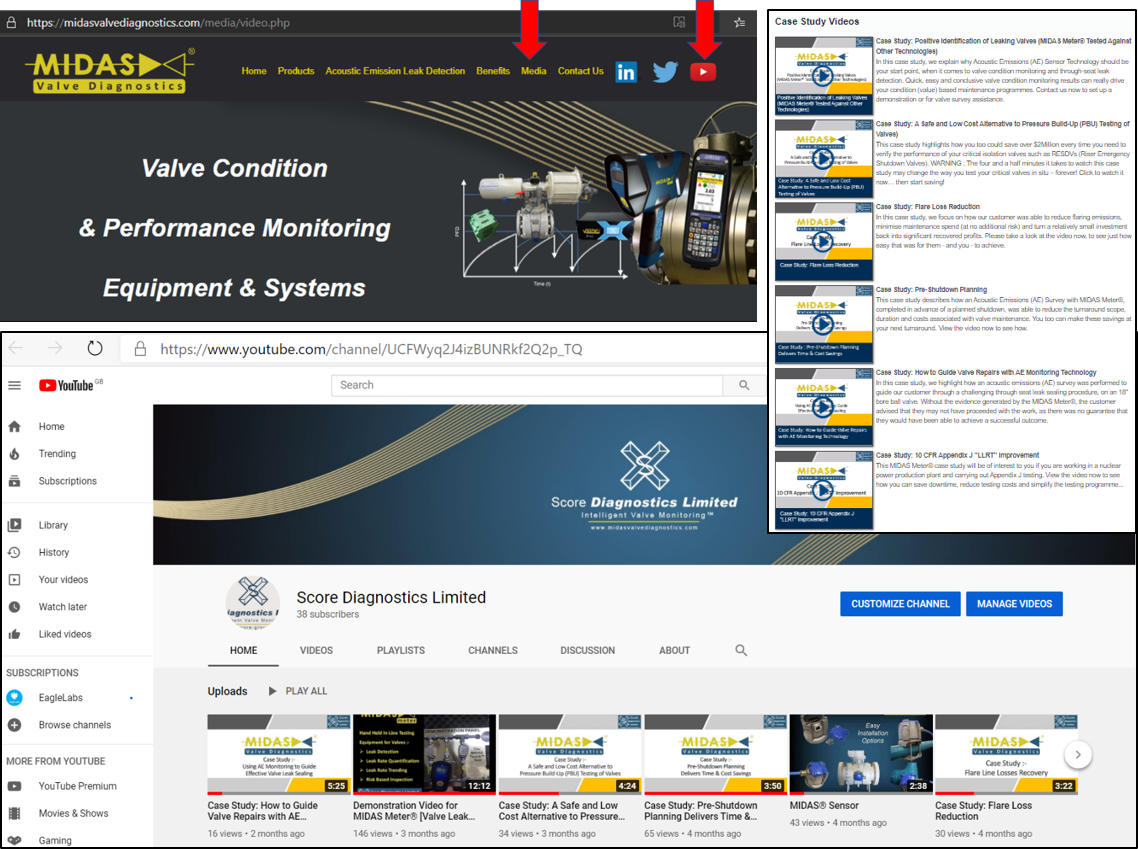

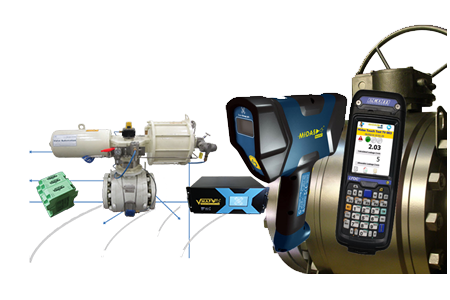

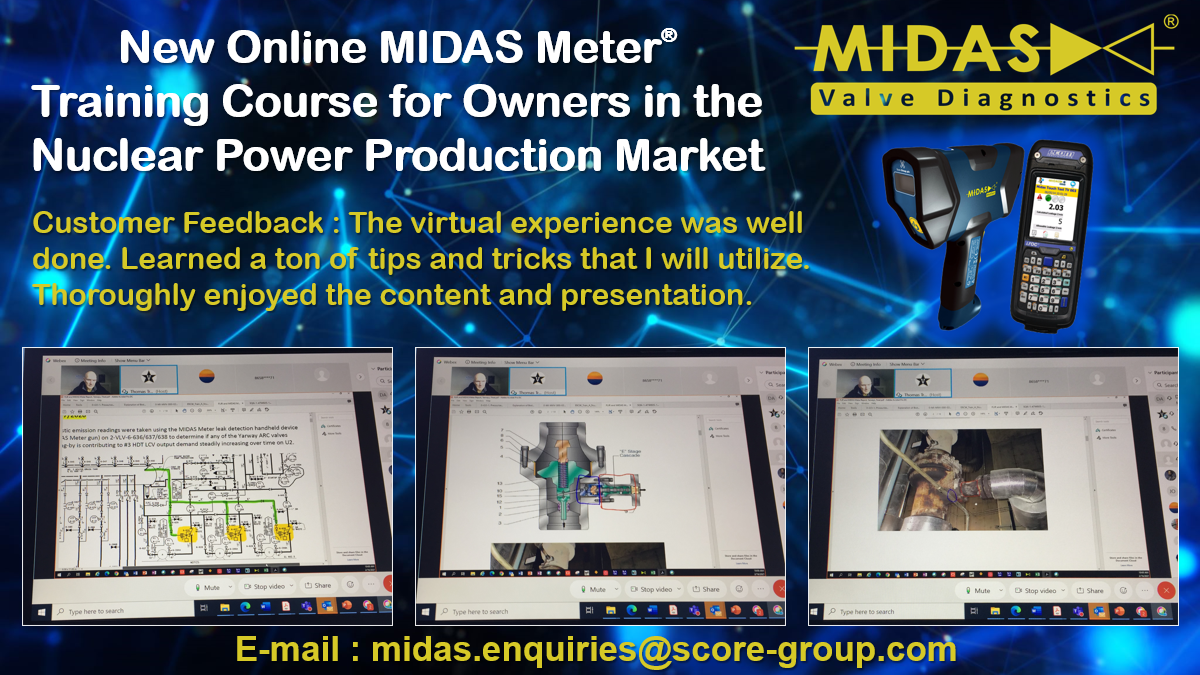

Score Diagnostics have recently developed a new series of video case studies, to help both our customers and team members alike, gain an insight into some of the key benefits of using the MIDAS Meter® valve condition monitoring device (such as troubleshooting problem valves, non-invasive valve testing inline, avoiding costly alternative valve testing techniques such as pressure build-up tests, pre-shutdown / turnaround planning, flare line loss and emissions reduction, backlog maintenance prioritisation and recovery, maintenance cost reduction, environmental protection, efficiency maximisation, etc).

We encourage you to view these consistently formatted short explanatory videos. We hope you find them to be of interest and value to you and your local customers, whom we recommend you share these resources with, as appropriate.

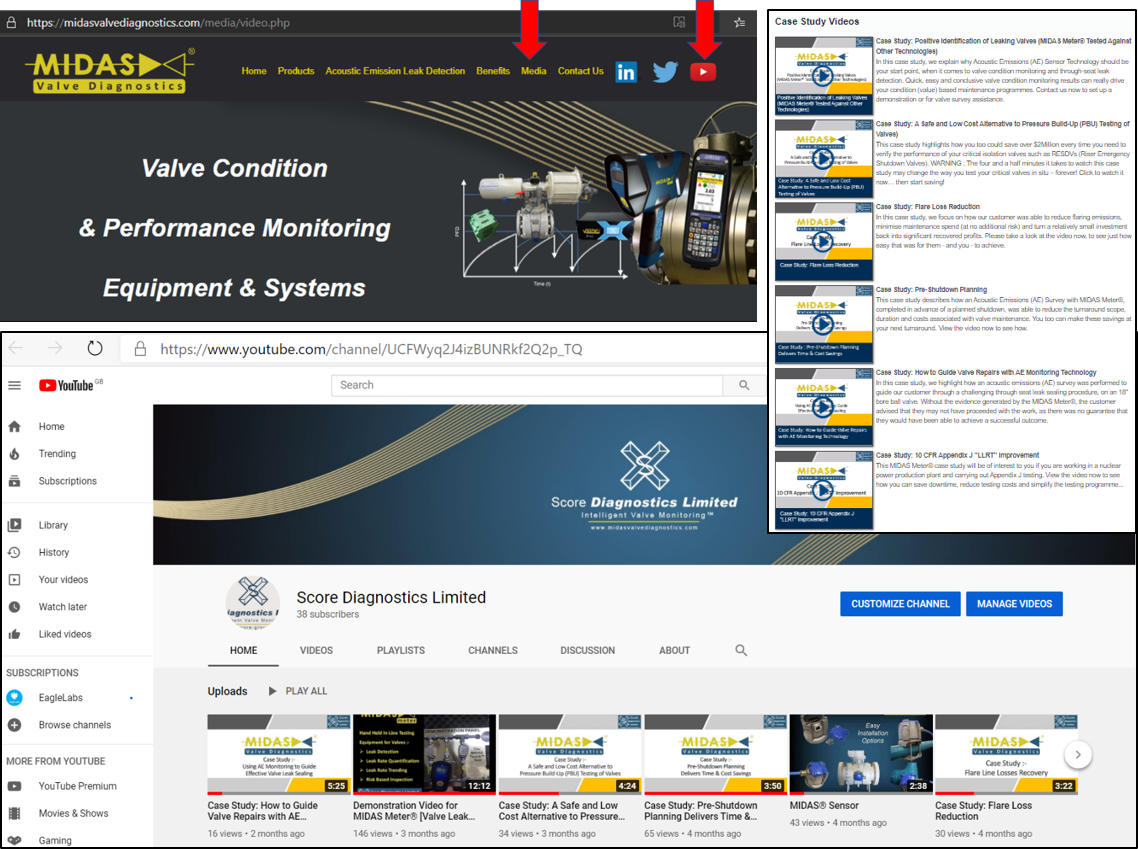

This latest series of case study videos add to an already extensive range of resources for MIDAS® Valve Diagnostics products and services which are readily available on our YouTube Channel, as well as the media sections on the MIDAS® Valve Diagnostics website. Don’t forget to subscribe / follow, to receive our latest updates as they are released.

Should you have any questions on reviewing these resources, or if you would like further information or a quotation for any of our valve condition monitoring equipment or services, please contact us immediately, by email, at; midas.enquiries@score-group.com We look forward to hearing from you.

to hearing from you.

to hearing from you.

to hearing from you.