It was an honour and a pleasure to be invited as panellists and speakers at the Plant Engineering And Maintenance Association of Canada (PEMAC), Fort McMurray Chapter, Online Professional Development Event on “Capabilities and Tools for Carbon Emissions Monitoring and Reduction”.

The mission of PEMAC Asset Management Association of Canada is to be “A professional association enabling excellence in maintenance, reliability, and asset management through collaboration, applied learning & leadership”.

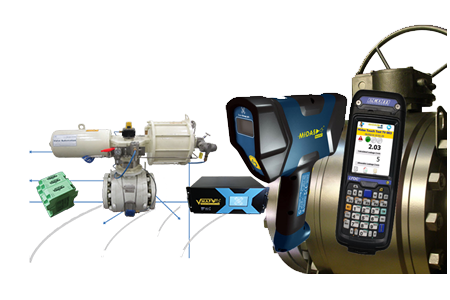

Given Score Group’s long track record and experience in optimising valve reliability through Intelligent Valve Management™, we are very well aligned to help them fulfil their mission.

Despite the 1am UK start time for one of our presenters, the audience was fresh and alert in Canada – who were of course 7 hours behind. We received some great questions and look forward to helping all stakeholders in attendance with their Fugitive Emissions / Carbon Emissions Reduction efforts moving forward.

If you would like to find out more about how we can help you reduce your emissions, please contact us now by email at; midas.enquiries@score-group.com