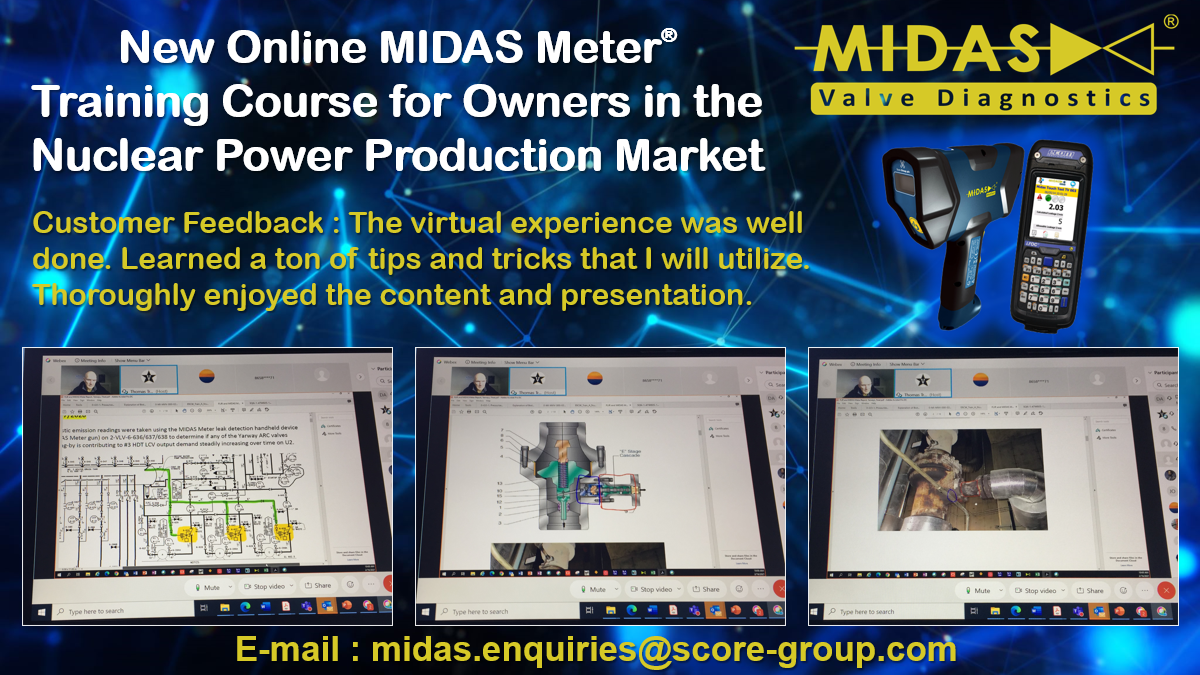

We were delighted to re-engage with some of our existing USA Nuclear Market owners and deliver a bespoke training course on MIDAS Meter® use and value maximization. Whilst many of our nuclear market customers have been using our technology for simple through-valve leak detection, there is now a real appetite to extract even more value, through leak rate quantification and periodic risk based inspections (RBI), to support leak rate trending over time and the operational advantages that this delivers. Part of this training session focused on consulting on real-life, ongoing valve leakage challenges, currently being experienced by the operators.

With the travel restrictions in place at present, this course was delivered online. A total of 13 delegates from 3 nuclear power plants attended the training and the feedback was excellent. A follow-up practical session – at the customer’s facility – is being lined-up for later in the year to ensure all operators are fully up to speed in the application of the technology and value extraction.

to hearing from you.

to hearing from you.